How are Lithium-Ion Batteries made: Focus cathode materials

- Description

- Curriculum

- FAQ

- Reviews

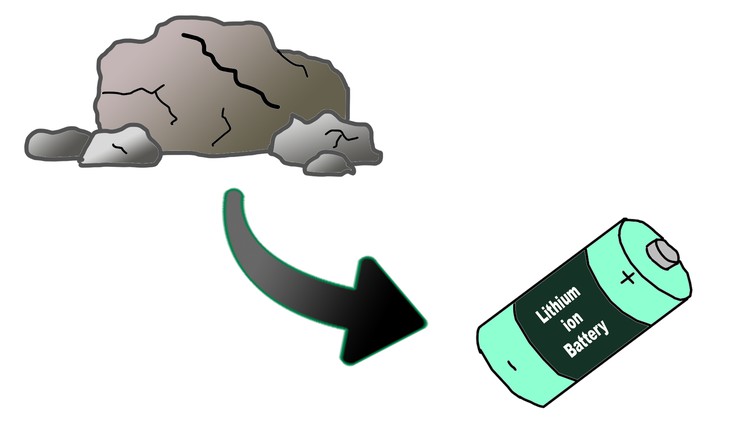

This class focuses on cathode materials used in today’s lithium-ion batteries (LiB).

Today’s cathode materials typically contain lithium, nickel, and cobalt compounds. In this class, you will explore how to find the resources to make the cathode materials in the first place and all the steps to the finished battery from scratch.

We will cover the mineral sources and mining stages of lithium, cobalt, and nickel. All the approaches to extract these metals from the ores, including details on pyrometallurgy and hydrometallurgy. We will study the processing of the final cathode material. And how these materials are assembled into a battery. We will also cover recycling options for spent lithium ion batteries.

The purpose of this course is NOT to teach you about electrochemistry, nor about battery performance or the pros and cons of specific battery types.

The specific focus of this course will be on nickel, cobalt and lithium extractive metallurgy and the synthesis and assembly of common cathode materials such as LCO, NMC and NCA.

- Learn how LiB works and what it contains.

- Study the mining and processing operations: the ores, the crushing and screening operations, the froth flotation.

- Become familiar with the extractive metallurgy of cobalt and nickel.

- Find out how to perform leaching, electrowinning, or solvent extraction to obtain pure nickel and cobalt salts.

- You’ll also cover a complete section on lithium refining: learn where to find lithium resources. How to process brines and lithium ores.

- Learn how to prepare the final cathode materials: including coprecipitation, lithiation, calcination, and cathode refining.

- Assembling into a battery: electrode preparation, assembly with anode and separator, winding, electrolyte filling, and initial charging.

- Recycle batteries: Explore battery life cycle, recycling flowsheet, treatment of small and large batteries.

- Get inspired to keep learning with the large amount of literature, websites and books I have picked out for you.

Familiarize yourself with making cathode materials for LiB hassle-free! This class is very comprehensive: I have about 10 years of battery experience (ass well in academia as in industry) and a total of 20 years of chemistry research under my belt. Therefore, this course will be your reliable guide for cathode material preparation.

-

3Overview "from Mine to Battery" the full FlowsheetVideo lesson

An overview of all steps needed to make cathode materials and get them in a battery

-

4A word to books and further readingVideo lesson

about books and publications...

-

5Inside a Lithium ion BatteryVideo lesson

You will learn the main component of a LiB battery

-

6Todays Cathode MaterialsVideo lesson

We will have a look to the most common cathode materials: NMC, LCO, NCA...

-

7How does a Lithium ion Battery works?Video lesson

A short description on how a LiB works.

-

8Further Reading: Lithium Ion BatteriesVideo lesson

Overview on Books, Websites and Literature about Batteries in General

-

9Chapter OverviewVideo lesson

Short Recap on the chapter construction on the flowsheet.

-

10Geology BasicsVideo lesson

Short overview on Terminology: what is a rock? A mineral? An Ore? Gangue Rock?

-

11Cobalt and Nickel: Minerals and OresVideo lesson

-

12Further Reading: Minerals and OresVideo lesson

-

13Crushing and Screening: Overview and EquipmentVideo lesson

Presentation of the general goals followed by an overview of crushing and screening processes.

-

14Crushing and Screening: Examples of a FlowsheetVideo lesson

An rudimentary examples of a flowsheet

-

15Crushing and Screening: The HydrocycloneVideo lesson

-

16Froth FlotationVideo lesson

-

17Further Reading: Crushing, Screening and Froth FlotationVideo lesson

-

18Chapter Overview and General GoalVideo lesson

Overview of the Chapter Pyrometallurgy along with Books used

-

19Simplified ProcessVideo lesson

Overview of the Pyrometallurgical Process with the different steps: Roasting, Smelting and Converting

-

20Details: Roasting, Smelting and ConvertingVideo lesson

More details in the three pyrometallurgical steps: Roasting, Smelting and Converting

-

21Further ReadingVideo lesson

Further Reading Section

-

22Chapter OverviewVideo lesson

Recap: Overview of the Chapter Hydrometalurgy

-

23Leaching: Principle and ExamplesVideo lesson

What is leaching, how does it work and how can it be used to leach Nickel-Matte.

-

24Refining: Goal and MethodsVideo lesson

Overview of the different Refining Steps, which will be presented in the next lectures

-

25Refining: Ion ExchangeVideo lesson

Overview how Ion Exchange can be used to remove impurity or clean up Co- and Nickel-containing solutions

-

26Refining: PrecipitationVideo lesson

-

27Refining: CementationVideo lesson

Cementation is also a form of precipitation, but using spontaneous redox-reaction.

-

28Refining: ElectrowinningVideo lesson

-

2933 Solvent Extraction: Goal and PrincipleVideo lesson

Overview of the Principle of Solvent Extraction and how it works

-

30Solvent Extraction: Scrubbing, Washing, StrippingVideo lesson

At the end of the extraction process, several posttreatment steps are needed: Scrubbing, washing, stripping

-

31Solvent Extraction: Examples and Coordination CompoundsVideo lesson

More details on Solvent Extraction: we will see an examples and have a look to coordinating agents

-

32Solvent Extraction: Further ReadingVideo lesson

-

33CrystallizationVideo lesson

-

34Spray PyrolysisVideo lesson

-

35Different RoutesVideo lesson

Routes if you want to avoid Pyrometallurgy Steps

-

41Chapter OverviewVideo lesson

Chapter Overview and Learning Goals

-

42Preparation Precursor MaterialVideo lesson

-

43Preparation Precursor in DetailsVideo lesson

-

44Preparation Precursor Post ProcessingVideo lesson

-

45Addition of Li-SaltsVideo lesson

-

46Lithiation and Calcination: Details in CalcinationVideo lesson

-

47Lithiation and Calcination : PostprocessingVideo lesson

-

48Cathode RefiningVideo lesson

-

49The End ProductVideo lesson

finally we have finished the cathode material...

-

50Alternative Approach: Sol-gel and Spray DryingVideo lesson

Alternatives to Coprecipitation Routes: Sol-Gel and Spray Drying

-

51Further Reading: Cathode MakingVideo lesson

-

52Chapter overview and assembly stepsVideo lesson

-

53Electroce, Cells, Module, Pack…Video lesson

-

54Mixing all cathode components and Preparing CathodeVideo lesson

-

55Drying, Calendering and AssemblyVideo lesson

-

56Bonus-Movie: How to build a pouch cell?Video lesson

Pouchell Making at Helmholtz Institute Ulm

-

57Winding and StackingVideo lesson

-

58Filling ElectrolyteVideo lesson

-

59First Charge and FormationVideo lesson

-

60Further AssemblyVideo lesson

-

61Further ReadingText lesson

-

62Chapter Overview + hoch much metals inside a batteryVideo lesson

Chapter overview and recap on how much metals are inside a battery

-

63Overview Battery Life CycleVideo lesson

-

64Example of a Battery Recycling FlowsheetVideo lesson

Description of the lifecycle of a battery

-

65Types of treatment of old batteriesVideo lesson

-

66Recycling: Further ReadingVideo lesson

External Links May Contain Affiliate Links read more